Meeting & Presentation

Binding Machines & Supplies

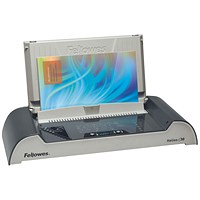

Binding Machines